- Home

- News

- What’s On

- Activities for Children

- Arts & Crafts

- Autos and Bikes

- Business events

- Car Boot & Auctions

- Charity events

- Churches & Religious

- Comedy

- Dance

- Days out & Local interest

- Education

- Exhibition

- Film

- Gardening & Horticulture

- Health

- Markets & Fairs

- Music

- Nature & Environment

- Spiritual

- Sport

- Talks and Discussions

- Theatre and Drama

- Business

- Local Information

- Jobs

- Deaths

- Charity events

- Contact Us

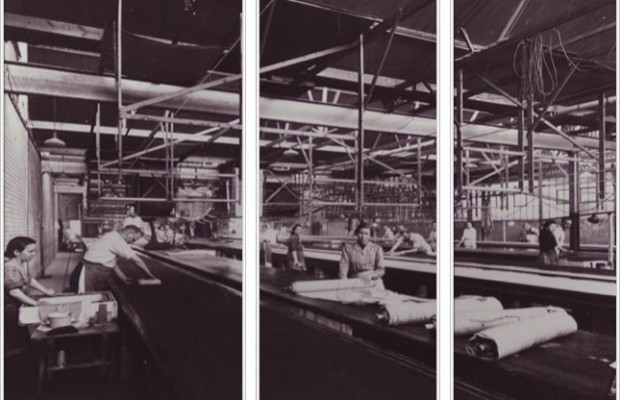

Textile firm in court over teenage apprentice’s injuries

A local fabric company has been fined after a teenage apprentice suffered severe injuries when his left arm was dragged around a machine roller.

The 18-year-old from Buxton had been trying to remove a crease from a roll of silk at Medaax Ltd when his finger became caught, pulling him in up to his armpit.

The company, which trades as Adamley Textiles from its River Mills site, was prosecuted by the Health and Safety Executive (HSE) after an investigation found workers were regularly exposed to dangerous moving parts of the machine.

Macclesfield Magistrates’ Court heard the employee had joined the firm as an apprentice at the age of 17. He had been operating a machine used to dye and wash silk when the incident happened five months later, on 6 November 2012.

He was in the process of winding the dyed silk onto a roller so that it could be removed from the machine when he noticed a crease and used his left hand to smooth it out.

As he did so, his finger became caught and trapped, pulling his arm into and around the roller. He had to be cut free and suffered injuries and fractures to his arm. He also suffered nerve damage which had limited the use of his left hand.

The court was told employees at Medaax needed to lift the cover on the machine to unload fabric but no system was in place to cut the power in an emergency, or to reduce the speed of the rollers.

The company has since installed a pull-cord emergency stop device and a ‘hold to run’ button on the machine, which means it automatically stops operating when the button is not being pressed. The machine can also now run at a lower speed for unloading the silk.

Medaax Ltd was fined a total of £24,000 (£12,000 for each offence) and ordered to pay £4,466.86 in prosecution costs after pleading guilty to single breaches of the Health and Safety at Work etc Act 1974 and the Management of Health and Safety at Work Regulations 1999.

Speaking after the hearing, HSE Inspector Deborah Walker said:

“A teenage worker suffered injuries because he was let down by the company responsible for his safety.

“He was a relatively new employee at the firm but his injuries could easily have happened to other workers as they were regularly exposed to the same hazard.

“The risk of workers’ arms being dragged in by machine rollers is well known in the manufacturing industry and it’s vital that firms act to improve safety. If the measures Medaax implemented following the incident had been in place sooner then the young worker’s injuries could have been avoided.”

You must be logged in to post a comment Login