- Home

- News

- What’s On

- Activities for Children

- Arts & Crafts

- Autos and Bikes

- Business events

- Car Boot & Auctions

- Charity events

- Churches & Religious

- Comedy

- Dance

- Days out & Local interest

- Education

- Exhibition

- Film

- Gardening & Horticulture

- Health

- Markets & Fairs

- Music

- Nature & Environment

- Spiritual

- Sport

- Talks and Discussions

- Theatre and Drama

- Business

- Local Information

- Jobs

- Deaths

- Charity events

- Contact Us

Paradise Mill to reopen this month

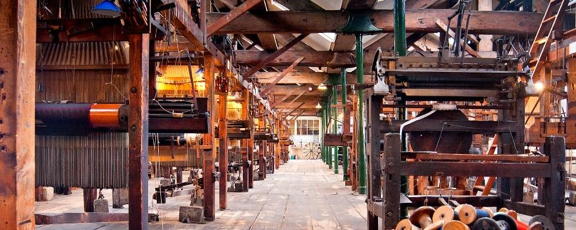

Paradise Mill, an original Grade II listed silk mill, designated by Historic England, and part of the Silk Museum, will reopen on February 17th following restoration work on the building.

Macclesfield was once the world’s largest producer of finished silk, with 5,000 looms and 71 mill factories. Built in 1862, Paradise Mill is now the sole survivor of Macclesfield’s industrial and creative past, housing the largest collection of silk Jacquard handlooms in their original setting and a design suite. The mill produced luxury silk goods for an international audience including retailers such as Liberty of London, until it finally closed in 1981.

A team is working on restoring two of the 19th century looms. Tour guides at the museum, Daniel Hearn, and Trish Halloran, alongside Rebecca Faragher, who is a trained weaver, are painstakingly undertaking the conservation of the 400-hook handlooms. Their work has been made possible by funding from the Association for Industrial Archaeology.

Daniel Hearn, one of the team who has taken on the task, says: “This restoration involves considerable effort, especially the building of a new Jacquard harness. There is more work to do, and still more to learn. Establishing a strong foundation in acquiring these skills means we are taking the first critical steps in ensuring that this niche type of Jacquard handloom weaving remains operational within the extraordinary time capsule that is Paradise Mill.”

Director of the Silk Museum, Emma Anderson, says: “The looms tell remarkable stories of silk production in Macclesfield. It is essential that they are kept in working order so that visitors can experience the incredible sights and sounds of these historically important machines. We need to revive and expand the technical knowledge of how to operate and care for them so they can continue to inspire future generations of weavers for years to come.”

Silk weaving has now joined the list of Endangered Heritage Craft Skills. Jacquard silk handweaving is a highly time-consuming skill to learn. The Silk Museum has secured funding from The Radcliffe Trust to work up a plan for the conservation of the looms alongside creative placements for emerging craftspeople.

The Museum is planning to return more of the collection of 26, Jacquard handlooms to working order in the future to keep this heritage skill alive for museum visitors and creative practitioners alike.

Weavers, Bea Uprichard and Ruth Farris who study at Manchester Metropolitan University’s Manchester School of Art have designed and woven a new silk – the first one to be created at the mill in decades.

Bea and Ruth explored the museum’s unique collections, looking at punch card sets, and the 20th century silk designs in the vast archive of pattern books. Their final design was inspired by these historic works but with their 21st century design sensibilities.

They have cut new punch cards and threaded them together to programme the restored loom.

The hand looms operated using punch cards, which employed a binary system of a hole or no hole to pass a set of instructions to the loom to tell it when to raise the warp. It was the precursor to modern computing, inspiring the likes of Charles Babbage and Ada Lovelace.

Punch cards were cut using a special machine and then linked together to create a programme, and this is how cloth would be woven in individual patterns, operated by hand.

Bea and Ruth, who are studying on the Textile in Practice course, tested out the design on a modern computerised Jacquard loom at Manchester Metropolitan University to ensure it was structurally balanced. They then undertook the task of drawing the design out on point paper and making a set of 192 punch cards. Each punch card corresponded to a line of the design.

The card cutting process alone, took more than five days. They used the original 19th century Devoge piano card-cutting machine, which was used in Paradise Mill when it was in operation.

They laced the cards together on the original lacing frame and stitched in the metal rods which carry the set on the loom.

Bea Uprichard, student at Manchester Metropolitan University, says: “We installed the set onto the loom and wove our first few rows of the pattern. It was magical! We then took it in turns to weave for two full days until we had about a metre of fabric – enough to cut off the loom.”

Ruth Farris, student at Manchester Metropolitan University, says: “Weaving on an old Jacquard loom is much more difficult than weaving on the looms we were used to. The process involves treadling with an exact level of force, using the picking stick to operate the fly shuttle with considered force, and using the sley to beat up each pick, all the while paying close attention to the quality of the silk and the performance of the loom.”

Director of The Silk Museum, Emma Anderson, says: “The work that our team is doing restoring the looms is exceptional. Added to this, to have the passion of Bea and Ruth working so hard to create this innovative design. It is living history.”

Part of The Silk Museum since 1984, Paradise Mill has undergone restoration with thanks to Allmand-Smith Ltd, who own Lower Paradise Mill. This has been made possible from a £309k National Heritage Memorial Fund award, which allowed the Silk Heritage Trust, who run the museum, to acquire a 125-year lease of the top floor of Paradise Mill from owners Allmand-Smith Ltd. Essential repairs to the roof and lift will now enhance the visitor experience and ensure it is accessible to all.

Paradise Mill, part of the Silk Museum, will reopen to the public on Saturday February 17th with special look around tours. You can find out more on the website https://www.thesilkmuseum.co.uk/

Guided tours of Paradise Mill will resume on February 28th, 2024.

You must be logged in to post a comment Login